Article in wired but others as well ultra cool use the knowledge, vision, wisdom of those who come to do.

Category Archives: Manufacturing Technology

Additive Manufacturing in Space- Two favorites in One!!!

3D / Additive Manufacture in Space! Two favorites in one!

And its an SBIR…Small Business Innovative Research, program, how cool is that on top? The SBIR program is a personal favorite of mine. It basically provides entrepreneurs and engineers with ideas with funds to develop a concept and put together a prototype then helps them either commercialize it or work with a big company to bring to the market or to NASA, USAF, Navy, Army, DoE, DoT, DHS etc. When done right which NASA, the Navy and to some extent the AirForce and Army have done this can provide fantastic bang for the buck. Its only downside is that it can be seen as a substitute for bigger development programs and it’s not. SBIR works for initial concepts, for components, basic materials, small-scale projects (App scale maybe) but it’s not enough bucks to do anything major. The only program that does something similar on a larger scale is DARPA, which is also a world leading organization in this area.

On Thursday, NASA announced the selection of 39 proposals for Small Business Innovation Research (SBIR) Phase II awards. …… Made in Space, a Silicon Valley company working on 3-D manufacturing in space.

Made in Space, Inc.

Moffett Field, CA

PROPOSAL TITLE: ISS Additive Manufacturing Facility for On-Demand Fabrication in Space

SUBTOPIC TITLE: ISS Utilization

Estimated Technology Readiness Level (TRL) Begin: 6 End: 8

TECHNICAL ABSTRACT

Made in Space has completed a preliminary design review of the Additive Manufacturing Facility. During the first half of Phase 1, the design went through conceptual development, simulation testing, cost analysis, and comparison testing of which off-the-shelf parts can be used. The deliverables for Phase I include a written report detailing evidence of demonstrated technology (TRL 5) in the laboratory and will outline in detail the path taken toward hardware demonstration for Phase II (TRL 6). The preliminary design is ready to be manufactured as an engineering test unit in Phase II. A feasibility study was created to demonstrate what could be fabricated for the inside of the ISS (parts and spares) and for the outside (possible satellites). It is anticipated that many of the sample uses that the AMF will make possible on-orbit have not yet been envisioned.

Better Pharmaceutical Manufacturing via Continuous Processing | MIT Technology Review

Better chemistry: To produce drugs in a continuous-manufacturing method, MIT engineers had to develop several new pieces of equipment, including this reactor, which enabled a faster reaction and eliminated the need for a toxic solvent.

This is a big breakthrough, this is part of the maker revolution though a long way from maker bot. In the long run such a system can be miniaturized and stocked with a range of precursors which will allow a single system to produce any number of different drugs on demand. In the early days such systems will be huge and hugely expensive but will make drug exploration exponentially quicker and less expensive. In the long-term the system makes the whole pharmaceutical infrastructure we have today obsolete…except that it will probably increase the need for scientists, physicians specializing in individualized medicine, etc, etc. Old jobs go away new ones come on-line. And the new ones will generally be much more about the outer edges of technology and the connection between people and between people and their machines, instead of embedding people as cogs in the machines.

The article is pretty high level but a good quick read on the topic.

It’s probably right because it’s clean and simple looking.

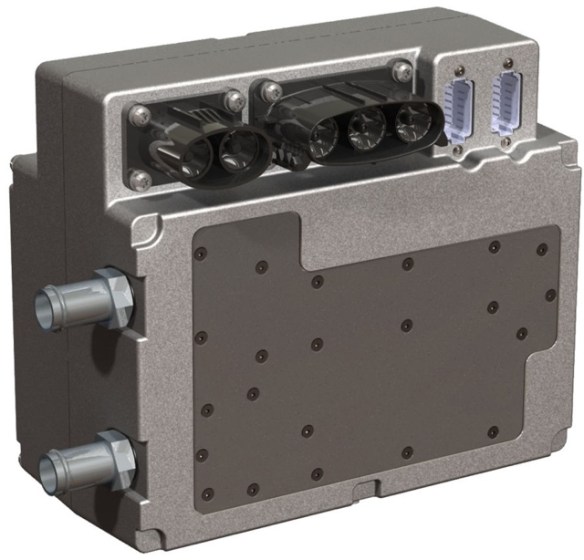

From SAE drivetrain e-newsletter

Arens’ automotive-hardened traction inverters with power ranges from 30 to 500 kW (40 to 670 hp) are for applications ranging from large transit buses and medium-duty trucks to hybrid passenger cars. With the Powerpac series, adapting an existing vehicle design to hybrid power does not involve intensive re-engineering. The Arens Powerpac 100-kW (134-hp) traction inverter features a high power density in a compact enclosure designed to fit with the battery, in the vehicle’s existing battery box. The inverter offers an insulated gate bipolar transistor-based design and is suitable for truck, bus, agricultural, and construction equipment applications. All Arens inverters feature cast enclosures sealed to IP67 with intelligent thermal protection.

Jenny Hessler

Very much like what my team at SatCom came up with for the AIPM Advanced (or Automotive depending on the audience) Integrated Power Module. The switches are bolted to the base the bus bar connects across them with capacitors integrated as close to the devices as possible and the gate drive and controller board on the other major flat face. Doubt any of the Aren’s team ever saw anything we did, it’s just the most economic and sensible use of surfaces and volumes to get the best performance.

Another Celebrity Seeker…and the Apple Culture

As far as I can see the whole mess with Mike Daisey is the common American confusion between celebrity and profundity. The Wikipedia entry above starts out :

“Mike Daisey (born 1976) is an American monologist, author, and actor best known for his full-length extemporaneous monologues…”

And that sums it up, he’s not a reporter, does not purport to be one and yet his monologuing is taken as a serious expose of Apple’s factories in China. The whole problem is that NPR got confused about what they had, it was in some ways not even Daisey’s fault…until he denied any fault as with so many things today, “..it wasn’t the break in it was the coverup…” inept spinning.

Now Apple knows that its old core and even its younger adherents are biased to the progressive/lefty “down with capitalism” side. Apple is also forced to build their products in China these days, they could not keep their products in the painfully but not prohibitively expensive category otherwise. They will not purposely turn a blind eye to abuses at their Chinese factories, especially as they know that they are likely to depend on Chinese customers for a lot of growth in the not too distant future.

Victor Russell Mead at Via Media has the best overall take on the Daisey mess, I won’t go into it any more.

However thinking about Apple and China does bring up other issues about manufacturing and the outsourcing of said. Two Questions of Apple:

- The iPad, iPhone, iPod are all flat, sandwich build products, why not automate the production and do it in the US?

- Aren’t you afraid of giving your products intellectual property to the Chinese, who have quite blatantly set about appropriating everything they can from anyone with good ideas?

And the answer is the same in both case. Apple has an extremely short product cycle most of the time and tries to keep their products under wraps until the last second. They use a very deep supplier base on the Asian shore to the fullest extent, the parts are cheaper and more available there, and Apple parcels the parts out so its hard for their competitors to figure out what’s coming until the last month or so before introduction. Final assembly of many gadgets is the most labor intensive part of the process and the hardest to automate, it can be done but if you are only going to build the product for a couple of years then completely rejigger why put the capital into a fixed site? And its the Social IP of how you design and proof out a product like the iPad in a very short time that is the secret sauce as much as anything else. And that IP the IP of the Apple way, the Apple Corporate Society, that gives them the edge, and its not one that anyone can copy easily. The whole infrastructure of design spin, parting out, having multiple products at various levels of development at one time, and staying mum, that keeps Apple ahead, their competitor’s head’s spinning and the Apple paparazzi merrily dancing in trail.

Dual use technology MOPs up?

A DUAL-USE technology is one that has both civilian and military applications. Enriching uranium is a good example. A country may legitimately do so to fuel power stations. Or it may do so illegitimately to arm undeclared nuclear weapons. Few, however, would think of concrete as a dual-use technology. But it can be. And one country—as it happens, one that is very interested in enriching uranium—is also good at making what is known as “ultra-high performance concrete” (UHPC).

Iran is an earthquake zone, so its engineers have developed some of the toughest building materials in the world. Such materials could also be used to protect hidden nuclear installations from the artificial equivalent of small earthquakes, namely bunker-busting bombs.

The above quote is from this wonderful Economist article, read it, as always clear prose, useful info well presented and minimal spin (&despite what some say that’s about as good as it gets spin wise if you want to explain/make a point.). It’s actually of general interest if you are interested in Civil Engineering or modern buildings and structures.

The point is that the US and others have been working on bunker busting for decades. The Massive Ordinance Penetrator shown dropping from a B52 above and in more detail below are the king of the hill right now.

Their reason for existence right now is to hold Iran’s nuclear bunkers at risk. The MOP is supposed to penetrate up to 200 ft of concrete:

The problem is that the work of Iranian engineers on tough concrete could mop up the MOP. The Iranians have added metal nano fibers and particles as well as fairly ordinary metallic, plastic and ceramic, whiskers, flakes etc to the mix to toughen the concrete in various ways. This work is being done to save lives world wide, including the US since it’s focus is on Earthquake damage reduction. But this is a wonderful example of dual use since exactly the same technology could make future bunkers all but impregnable to conventional weapons, which big as it is the MOP still is.

Bottom line if the best of the best tech were used they might get 6 or more times the strength and testing has shown just doubling concrete strength reduces penetration by more than half!

This is not good news and probably explains this:

Congress ‘Urgently’ Approves $82 Million To Improve Its Biggest Bunker-Buster

Despite this:

The 30,000-lb Massive Ordnance Penetrator Bomb Works So Well It Earned A Rare Honor

It would seem we may soon get a chance to see if the Iranians were smart enough to use the super concrete vs if our super bunker busters can slam, blast, burrow their way in. There is also the question of corruption, in a vastly corrupt civil society using expensive concrete which probably looks like any other concrete is an invitation for shaving. Many is the time when a fortress has fallen because of under spec materials. Also you have the long term espionage and internal strife driven sabotage the story is that bunkers for Nazi super Vengeance weapons were sabotaged by the addition of small amounts of sugar to the mix drastically weakening it.

This would all be a wonderful background for a comedic farce, if so many people’s lives were not at risk.

Enough said….

Nano Robots Move Out

A fascinating set of articles came out recently discussing the progress in micro and nano robotic techniques above. Is the picture from a short piece in IEEE Spectrum discussing the work of Dr. Ada Poon at the Standford Poon Group who are working on medical applications of beamed power.

The basis is this technical paper (PDF). Which talks about the chip, it essentially couples the beamed energy with a tiny antenna and converts the energy to a form needed to drive the chip using a electromagnetic propulsion fabricated on chip. Very cool. I will also point out that the Poon Group appears to be reasonably focused, some similar organizations I have run across or worked with have gotten way too diffuse and seem to wander off topic all the time. Dr. Poon is doing a good job focusing on some key enabling technologies in the field.

So every battle platform needs its weapons, and what do you know these guys seem to have just the ticket.

Researchers at the Wyss Institute for Biologically Inspired Engineering at Harvard University have developed a robotic device made from DNA that could potentially seek out specific cell targets.

Obviously they are looking to ways to use this in the form of a more traditional delivery system, say a shot, but the Dreadnought could also use these for delivering deadly loads into exactly the right spot possibly repeatedly over time without repeated shots etc.

On its own very cool, in combination with everything else going on, mind-blowing!!

And yet we also complain about the costs of medicine. The reason that money is put into these efforts is both altruistic and profit driven:

- Medicine is after all about making life better for human beings

- These techniques promise profound effects with minimal collateral damage

- These devices can be fabricated in their thousands using ultra clean and precise techniques that will both lower cost and improve performance.

- The price performance should move towards a Moore’s Rule like model of decreasing price AND increasing performance on a steep slope.

- Conditions untreatable today will be treatable

- People who would have died will live…some with health issues that will make them a drain on the economy.

- Early clinical trials and during ramp up and cost recoupment the prices will be high because of limited supply and price controls…and people will complain about the cost of medicine.

And so the cycle will go on. Do not take my screeds against Health Care costs and the Medical Establishment as any kind of Luddism, I want more technology more quickly, its the only path to better human lives. What I hate is the almost Medieval Economic model of the existing ME in the US.

3D printer builds a Lower Jawbone Replacement

This piece of news popped up all over earlier this week, but the Technology Review piece though short gives it some context. The rapid advances in imaging, tissue creation, stem cell technology, bio compatible materials, low impact surgery and 3D fabrication are being brought together to make things possible that were once fantasy and to eventually overtake transplants in the traditional sense.

While this is fascinating from a sci-fi writer’s viewpoint, the reality is something close to awe-inspiring.

New Proto Type Texas Flashlight – handy to have to walk the dog or take care of any little problem that might come up

Aside

Now..THAT’s what I’m talking about!

Mirasol the Butterfly Wing Display

I had heard about this technology several times over the years and had not realized that Qualcomm had commercialized it and is actually selling some units though they have not yet had a big ‘insertion’ win as like Nook, Kindle or the like. Unfortunately the first application the Kybo Reader is disappointing and if Qualcomm is not careful it could relegate the technology however good, to backwater.

Mirasol is like eInk a micro machine reflective display and not an emitter of light like an LCD, AMOLED even a plasma display is. The early insight that lead to the Mirasol is that the ‘scales’ on the wings of a butterfly get their vivid colors from an optical ‘trick’ rather than from brute coloration. The scales are very thin and essentially colorless, made of that basic creep bug shell stuff, chitin. The scales are made up of layers of transparent chitin of varying thickness. Light passes through the first layer and is selectively reflected because the thickness of the layers creates an optical cavity that selectively reflects light of a certain frequency while absorbing other frequencies.

Official description Here: Mirasol is made up of millions of pits with reflective bottoms with a multi layer thin-film ‘scale’ floating in the pit. The pit is a form of capacitor that can be positively or negatively charged, in one state the ‘scale’ floats to a position where the pit is a light trap, so it looks black, in the other state the ‘scale’ floats to a position where it reflects Red, Green or Blue very strongly. While changing charge state takes energy once changed there is all but no power demand. The ‘floating’ up and down is over a very short distance and happens very quickly, so you can create a video image with the technology, even in video mode its much less energy intensive than an LCD.

Since it is reflective not emitting it is sunlight readable, in fact like a book the brighter the light the better. It’s an efficient reflector so it’s actually quite readable in dim light and would need only a modest book light to make it readable in the dark. This may make it marginally less compatible with capacitive touch screens, but its possible that other technologies will replace the capacitive screen (I hope) like this interesting concept that turns any surface into a multi-touch interface.

This technology seems ideal for an eReader like the Nook Color that is not intended as a full function tablet but wants to be more the an eReader (eInk really sucks at anything other than page rendition) though it’s quite possible the technology will come on gangbusters for all portables if the technology is really as good as it purports.

Who is Qualcomm and why does it seem strange for them to be in this business? Qualcomm is the company that developed the CDMA (code division multi access)technology used in many phones today, as well as related technologies and has managed to leverage that into one of the significant if somewhat odd players of the mobile tech. For many years they were pushing the PCA phones, the first digital microcell technology that disrupted the old analog cell phone monopolists. THough they started on the digital side eventually they got into the business of designing the chip set for the radio in the phones. I believe it was Qualcomm that effectively proved that SiGe and even pure Si could compete with GaAs chips for the high performance radio frequency parts. Especially when they showed that they could integrate the radio on a single chip and eventually on the chip with the digital parts. They were an early SOC (system on a chip) player. Now they license the ARM technology used in most smart phones and they build one of the competitors in the tablet and smartphone processor offerings. The work on Radio frequency devices gave them experience in MEMS (micro electro mechanical systems) which is the manufacturing technology behind Mirasol. I would imagine that they see a long-term synergy between all these pieces, they essentially build the complete electronic kit set (including smart screen) that a OEM (original equipment manufacturer ) can put in a custom case with their choice of battery and interface thus providing the ability for and OEM to have highly distinctive product without having to have the expensive engineering resources required to design custom electronic ‘guts’ of their custom (semi custom really) product.

Its a bit like Chrysler designing a car kit, the sub frame, engine, suspension, transmission, electric and electronic systems that some custom builder then can take and design a shell around, making it into a sedan, hatchback, coupé, minivan, pickup truck, delivery van, taxi etc….which come to think of it is how many car companies work these days with ‘platforms.’

Sorry used to play in these waters a bit, and still find the technology and business fascinating, Qualcomm is an interesting success story who flies under the radar most of the time. I think the are like a company I work with today, they feel that constant PR flack barrage some companies put out are more about ego and stock price massaging than anything else, while being both a waste of money and potentially self-defeating by giving away too much information and setting the participants up for a fall.