A short but instructive piece on wireless technology and networking, mind opening.

Category Archives: Technology

Jaja: Worlds first pressure sensitive iPad Stylus

This project to develop a better iPad Stylus is a Kickstarter, crowd sourced project, i.e. the project is funded by putting the prospectus on the website and asking for a set amount of funding to get to the next level. This is an approach to funding that is taking off big for many types of effort and holds a great deal of promise for W.R.Mead’s Post Blue Model (on which more later.)

The project itself looks reasonably conceived and has what in some circles is called off ramps, that is pieces of the technology that may be of value in their own right.

I do have to say that eventually I think a non-capacitive system, maybe even an old style optical dig pen will be needed in addition to the capacitive if the iPad is to reach its peak functionality. Which is what this Technology Review blog post, Will Designers Take to the iPad3? talks about. The answer in my opinion is no, I am not a professional but am somewhat ProAm and I find that while the iPad has its liberating effect (frothed about elsewhere) it still has some irritating downsides at times.

Nano Robots Move Out

A fascinating set of articles came out recently discussing the progress in micro and nano robotic techniques above. Is the picture from a short piece in IEEE Spectrum discussing the work of Dr. Ada Poon at the Standford Poon Group who are working on medical applications of beamed power.

The basis is this technical paper (PDF). Which talks about the chip, it essentially couples the beamed energy with a tiny antenna and converts the energy to a form needed to drive the chip using a electromagnetic propulsion fabricated on chip. Very cool. I will also point out that the Poon Group appears to be reasonably focused, some similar organizations I have run across or worked with have gotten way too diffuse and seem to wander off topic all the time. Dr. Poon is doing a good job focusing on some key enabling technologies in the field.

So every battle platform needs its weapons, and what do you know these guys seem to have just the ticket.

Researchers at the Wyss Institute for Biologically Inspired Engineering at Harvard University have developed a robotic device made from DNA that could potentially seek out specific cell targets.

Obviously they are looking to ways to use this in the form of a more traditional delivery system, say a shot, but the Dreadnought could also use these for delivering deadly loads into exactly the right spot possibly repeatedly over time without repeated shots etc.

On its own very cool, in combination with everything else going on, mind-blowing!!

And yet we also complain about the costs of medicine. The reason that money is put into these efforts is both altruistic and profit driven:

- Medicine is after all about making life better for human beings

- These techniques promise profound effects with minimal collateral damage

- These devices can be fabricated in their thousands using ultra clean and precise techniques that will both lower cost and improve performance.

- The price performance should move towards a Moore’s Rule like model of decreasing price AND increasing performance on a steep slope.

- Conditions untreatable today will be treatable

- People who would have died will live…some with health issues that will make them a drain on the economy.

- Early clinical trials and during ramp up and cost recoupment the prices will be high because of limited supply and price controls…and people will complain about the cost of medicine.

And so the cycle will go on. Do not take my screeds against Health Care costs and the Medical Establishment as any kind of Luddism, I want more technology more quickly, its the only path to better human lives. What I hate is the almost Medieval Economic model of the existing ME in the US.

AWST | Electric Propulsion for Airliners

Green Operations

Taxi Electric

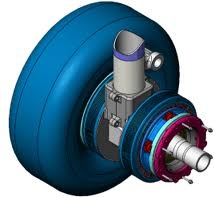

Powered wheel-drive systems promise to save fuel and reduce emissions at airports

Graham Warwick/WashingtonTaxiing to and from the runway on engine power may soon be a thing of the past as development of electric wheel-drive systems progresses, with the promise of reducing fuel consumption, emissions and noise—and potentially increasing airport capacity.

EasyJet will be the first airline to test an electric taxiing system being developed by Honeywell and Safran. Operational trials on the Airbus A320 are expected to begin in 2013. Lufthansa and L-3 Communications tested an electric-taxi technology demonstrator on an A320 at Frankfurt in December. WheelTug plans to demonstrate a system on a Boeing 737-800 in May, “almost certainly in North America,” the start-up says.

The Honeywell/Safran electric green taxiing system (EGTS) uses electric motors on the main landing-gear wheels, powered by the aircraft’s auxiliary power unit (APU). L-3’s GreenTaxi system also powers the main wheels, but WheelTug’s approach is to drive the nosewheels. German aerospace center DLR demonstrated a powered nosegear on an A320 at Hamburg in June 2011, with the electrical power coming from a fuel cell.

WheelTug is testing its motors in the laboratory and expects to begin tests of the complete wheel package in March, says CEO Isaiah Cox. Details of the May demo have yet to be announced. WheelTug is on track for certification and first deliveries for the Boeing 737NG in mid-2013, he says, and talks have begun with A320 operators. Israel airline El Al has signed a memorandum of understanding, and Cox expects to have “1,000 aircraft in backlog” by late this year.

The Honeywell/Safran partnership has acquired an A320, based at Montpelier, France, which it is using to understand loads and deflections on the landing gear. This aircraft will be used for tests of the EGTS beginning this year, says Brian Wenig, vice president of business development at Honeywell Aerospace. Certification of the system for retrofit and forward fit is targeted for 2016.

Lufthansa Technik and teammates L-3, Airbus, Lufthansa and Frankfurt Airport operator Fraport are scrutinizing data from 14 hr. of taxi trials and will complete an economic benefit analysis in March before deciding whether to proceed to a prototype system, says Christian Mutz, project manager of innovation for Lufthansa Technik.

The GreenTaxi demonstrator used off-the-shelf vehicle motors from German subsidiary L-3 Magnet-Motor. Installation required removal of the brakes from the outer wheel on each pair. A container in the cargo bay provided power conditioning and liquid cooling, which Mutz says proved not to be needed, as the motors stayed cooler than the brakes.

Weight is critical, and the Lufthansa team is looking at a lighter pushback-only system as an alternative to the full capability, as well as a hybrid of the two. A pushback-only system would propel the aircraft at 3 mph, compared with a full system that would be capable of taxiing the aircraft at 30-40 mph, Mutz says.

Able to propel the aircraft at up to 28 mph, WheelTug weighs 300 lb. but is “flight weight”-neutral, as less fuel is required for taxiing, the company says. Minimum fuel burn for a 737 taxiing on one engine averages 15 lb./min., and crews typically add 30 min. of fuel weighing 450 lb. for contingencies. Powering the wheels from the APU cuts taxi fuel burn by up to 85%. “Instead of over 200 kg [440 lb.] of taxi contingency fuel, I can load 60 kg, and have the same operational flexibility,” says Chief Pilot Joseph Goldman.

WheelTug’s business plan is to supply systems and spares free to airlines and share the demonstrated savings. “We can show savings to airlines of $600,000-800,000 a year,” says Cox. “That compares with $1.5-2 million a year for reengining.” Honeywell “conservatively estimates” that the EGTS will save an average $160 per segment, and 130 tons of fuel per year per aircraft, for an A320 or 737 operator, says Wenig.

There is still debate over the right approach. Honeywell/Safran and L-3/Lufthansa say the capability to taxi in all conditions can only be provided by powering the main wheels, as there is not enough weight on the nosewheels to provide the required traction. “We have done tests, and demonstrated operation in ice and snow,” counters Cox.

Other potential benefits of electric taxiing include shorter turnaround times and the ability to position aircraft on the runway at noise-constrained airports so takeoffs can begin as soon as the curfew is lifted, generating more slots. But engine makers are concerned about the lack of warm-up time that could result.

A picture from Chorus Motors, who owns WheelTug, the motors are in the nose wheel which has no braking system so has lots of room for the motors (don’t get me wrong these are powerful motors for their size weight.)

The issue mentioned above and main reason that this is starting on the 737 and A319 is that these are both big and small at the same time.

Compare the landing gear in the pictures below one of a 737 the other of its biiiiig brother the 777.

There is much more, % wise, weight on little bro’s front wheel. With friction etc you have a practical propulsion system even in crappy frigid/icy weather, after the planes been sitting for a long time, and the tires have flat spots where they contact the ground. With the 777 there is no way that the front wheel can haul that big boy around.

The article discusses work on main gear but here you have to integrate around the brakes. Now there are reasons this would be good beyond taxing but the brakes are hot and dirty, a much tougher environment and for a big boy you would need a lot more than two driven wheels which makes cabling and drives even more of an issue. But at the end of the day this is probably the way aircraft will move on the ground in twenty some years and those future versions of us will wonder why it took so long.

Testing out a main gear electric taxi concept, L3/MagnetMotor and Lufthansa.

Ferret under the cars, the tables, the … Uh shouldn’t go there…

Another use for a robot, inspecting for bombs etc, this is the general-robotics Ferret. I find the name of the company interesting it’s turned up in SciFi forever, following General Electric, General Motors, General Mills, General Atomic, etc, etc, it became a claim on greatness then a cliche. The parent company is in electrooptics and it’s influence can be seen in the video glasses. Does not take away from a great idea. I wonder if the inventor was watching his Rumba vacuum under the couch when he had the flash?

From Defense Tech

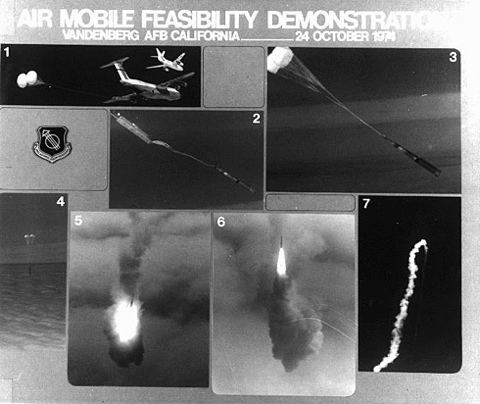

This reminder of fun times past, though one wonders about the prayers of the C5 pilot prior to ignition. I remember seeing this as one of the options explored for the Peacekeeper ICBM follow on to The Minuteman. Must admit that it seems pretty crazy cost wise and if you kept them on the ground most of the time little different from the bomber force. Maybe it made some sense, fly as close to the border as you want then toss in at a shallow angle, mixing up the attack as it were. Of course by the time this was really feasible, there was no point…and history seems to say that much of this kind of thinking was wasted time and energy, the BOOGEYMAN, was only ever a boogeyman, and probably more worried about what we might do to him than what he could do to us.

3D printer builds a Lower Jawbone Replacement

This piece of news popped up all over earlier this week, but the Technology Review piece though short gives it some context. The rapid advances in imaging, tissue creation, stem cell technology, bio compatible materials, low impact surgery and 3D fabrication are being brought together to make things possible that were once fantasy and to eventually overtake transplants in the traditional sense.

While this is fascinating from a sci-fi writer’s viewpoint, the reality is something close to awe-inspiring.

Autonomous Quadrotor Video, cool to be creepy

This video of swarming Autonomous Quadrotors has made the rounds, I guess I’m just adding my bit to the noise, this isn’t that surprising but it seems to me just one more indication that the world is the cusp of great change. The article at Wired is short but has some other interesting links.

New Proto Type Texas Flashlight – handy to have to walk the dog or take care of any little problem that might come up

Aside

Now..THAT’s what I’m talking about!

A few chemicals and a microwave and see what you get

High-efficiency thermoelectric materials could lead to new types of cooling systems, and new ways to scavenge waste heat for electricity. Researchers at Rensselaer Polytechnic Institute in Troy, New York, have now developed an easy, inexpensive process to make such materials.

The materials made by the RPI team already perform as well as those on the market, and the new process, which involves zapping chemicals in a microwave oven, offers room for improvement. “We haven’t even optimized the process yet,” says Ganpati Ramanath, a materials science and engineering professor at RPI. “We’re confident that we can increase the efficiency further.”

What caught my eye here is that the material is a form of nano particulate, its produced in an evidently very simple process and it has a very high efficiency. This type of technology as the article notes could have a great number of applications. In a car one could conceive of replacing the mechanically driven alternator with something like this or supplementing it, this would essentially be using waste heat to provide electricity and would increase gas mileage. There are many other places where heat scavenging would make sense and have an impact if the materials and system were cheap enough. This goes back to a fundamental issue, energy efficiency costs money and if the cost of burning a tiny fraction more fuel over the life of the system (which can add up to biggish $) is less than the energy scavenging equipment then the equipment will not be installed unless the added cost is passed on to someone.