When you think about it we’re built up from billions of smaller common modules with a lot of minor variations, why shouldn’t our infrastructure be the same?

MIT researchers have developed a lightweight structure whose tiny blocks can be snapped together much like the bricks of a child’s construction toy. The new material, the researchers say, could revolutionize the assembly of airplanes, spacecraft, and even larger structures, such as dikes and levees.

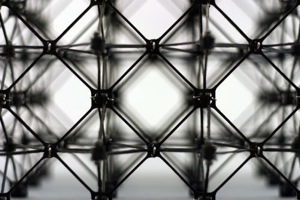

Assemblies of the cellular composite material are seen from different perspectives, showing the repeating “cuboct” lattice structure, made from many identical flat cross-shaped pieces.

PHOTO COURTESY OF KENNETH CHEUNG

Credit: © CC-BY-NC-SA Kenneth C. Cheung

Part production for reversibly-assembled cellular composite materials, slicing from stock produced by a multiplexed fiber winding method. Credit: CC-BY-NC-SA Kenneth C. Cheung

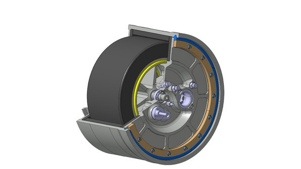

Test apparatus with reversibly-assembled cellular composite materials. Credit: © CC-BY-NC-SA Kenneth C. Cheung

If you can’t tell that last picture is a load cell, an instrument for applying precisely controlled loads to CRUSH YOUR ENEM…. uh, I mean… test the strength of a part or structure.

Read more at:MIT

or at:PhysOrg

or at: 3Ders

Obviously the MIT press piece is the base, but the others each have a little different insight.