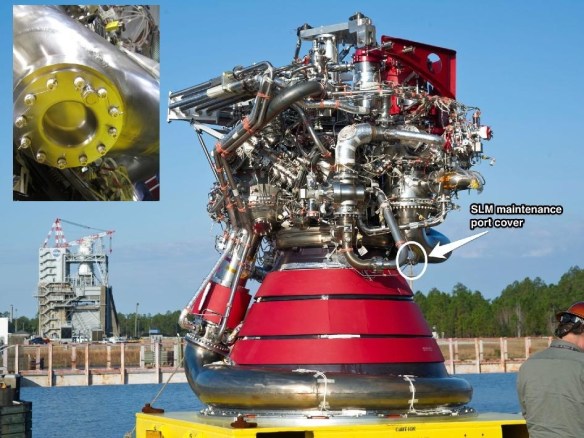

A 3-D printed table … with holes and all. Photo: rosemarybeetle / Flickr

WIRED http://www.wired.com/opinion/2013/05/an-insiders-view-of-the-hype-and-realities-of-3-d-printing/

3-D printing is indeed an important fabrication technology, because it has the marvelous ability to make anything regardless of the complexity of the form.

BUT

Everything from cost and time to amount of material increases exponentially: specifically, to the third power. So if we want something twice as big, it will cost 8 times as much and take 8 times as long to print. If we want something three times as big, it will cost about 27 times more and takes 27 times longer to print. And so on.

Love simplifying memes, these are two great ones that help the mind focus on the issues involved when ‘discussions’ dealing with potentials are taking place.

Also in the article:

The reminder that these are not replicators, not yet anyway.

AND

That many of the technologies enabling 3D printing are enabling CNC machining, laser-cutting, robotics and more, at DIY / hobbyist scale.